Hot Tack Testing|hot tack strength : trading Hot Seal Strength (Hot Tack) of Thermoplastics ASTM F1921 method B . Resultado da Tufos gratuito - Grupos de Telegram e Whatsapp Brasil. 17 de agosto de 2022 Por. Vamos revelar tudo sobre tufos gratuito. Também há a .

{plog:ftitle_list}

webInício Nota Fiscal Eletrônica NFs. NFs. Caso não consiga visualizar o conteúdo dessa página, clique aqui. Av. Rio Branco, 304 - Prata, Campina Grande - PB. Telefone: 83 .

Intertek evaluates product seal strengths by performing Hot tack testing according ASTM F1921 (method B). Hot tack measures the strength of heat seals formed between thermoplastic .The test sample is attached to a load cell and is placed briefly in a hot oven and .Stretch-Wrap packaging film testing on quality and material behaviour. Intertek .Hot Seal Strength (Hot Tack) of Thermoplastics ASTM F1921 method B .

If the hot seals have inadequate resistance to these forces, breakage can occur during the packaging process. These test methods measure hot seal strength and can be .Hot tack tests will help manufacturers choose the optimal heat-sealing parameters. Hot tack directly affects the filling efficiency and the rupture rate of the bag. Heat seal performance is often used to indicate the containment .

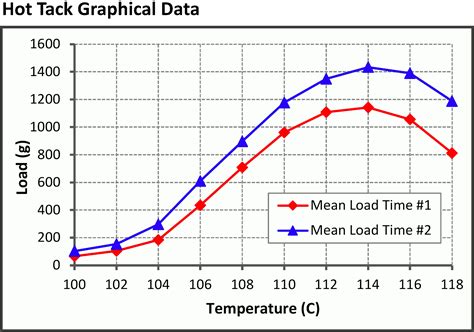

Later known as the DTC hot tack tester, this device consists of two heated sealing jaws: clamps to hold the test sample with the lower clamp dropping to pull the seal apart, a transducer to .Hot Seal Strength (Hot Tack) of Thermoplastics ASTM F1921 method B data for optimizing heat seals in film and flexible packaging materials. Hot tack measures the strength of heat seals formed between thermoplastic surfaces of flexible .This paper, however, will discuss two important aspects of hot tack testing: the multilayered structure with a “hot tack” sealant and methods for relating test results to actual packaging .

Hot tack testing and heat seal testing with an Enepay test instrument is the most accurate and productive way to generate your packaging film seal curves. Fully automated with Enepay's Pilot software, our test systems follow ASTM .ASTM F1921 - Standard Test Method for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and Blends Comprising the Sealing Surfaces of Flexible s.

Hot Tack Testing Hot tack is the strength of heat seals formed between thermoplastic surfaces of flexible webs, immediately after the seal has been made and before it cools to room temperature. Hot Tack test makes it possible to determine the seal strength and appropriate sealing parameters directly after the heat sealing process. Hot Tack Performance Test is used to determine hot tack property test for plastic films, laminated films and other packaging films. Meanwhile, it is also use.At Cell Instruments, we’re dedicated to advancing the precision of testing and measurement. With over 25 years of leading industry innovation, our mission remains clear – to provide accurate, durable, and state-of-the-art instruments .

Thermal tack is an important property of packaging materials such as plastic films and composite films. QualiTack Hot Tack Tester can quickly measure the hot tack strength of plastic film substrates and flexible packaging composite films after heat sealing at set temperature and pressure, imitate the production process of packaging bags, and directly conduct peeling .ASTM F1921 - Standard Test Method for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and Blends Comprising the Sealing Surfaces of Flexible s . Hot tack is the strength of heat seals formed between thermoplastic surfaces of flexible webs, immediately after the seal has been made and before it cools to room temperature. .Objectives: Hot Tack Tests measure the strength of a seal while still warm. Methods, Results, & Limitations: Test methods, results, and limitations are very similar to peel strength tests, except force is applied instantaneously, before the seal can cool.

Hot tack is a primary function of flexible packaging. It has taken on more emphasis with the development of sealant copolymers and ionomers as well as the development of coextrusion to meet the packaging industry's need for heat seal reliability when running at high speeds with more demanding configurations. As with many new terms, hot tack has not been precisely defined .The 75-50 SL-10 Hot Tack Tester and Seal Tester, is the most precise . and consistent heat seal tester in the packaging industry! Testing capabilities include heat sealing, heat seal testing . and hot tack testing. The SL-10 Hot Tack and Heat Seal Tester provides critical information needed to determine ideal sealing conditions for packaging films.The hot tack temperature range, this is the temperature range in which the required hottack strength is obtained. Failure Mode (Equivalent to ASTM F88) **Please note that this test description is intentionally generic in nature and aimed at providing a descriptive summary to enhance test understanding. Standards can be obtained from appropriate .If you would prefer to let us take care of your testing in the RDM LAB, simply complete the Heat Seal and Hot Tack Testing form HERE and one of our team will contact you with more information. Add to Enquiry. HS-2 Laboratory Heat Sealer. For precise measurement of heat sealability of flexible packaging. Produces seals up to 50mm long [.]

The RDM HT-1XS Hot Tack Tester measures the strength of hot seals enabling selection and compliance testing of suitable flexible materials for packaging applications. Precise control of sealing process variables (temperature, pressure, and time) in production then enables an optimal balance between material specification, packaging machine .

Recommended testing instruments. The HTT-02 Hot Tack Tester from Cell Instruments is a cutting-edge instrument designed for measuring the hot tack and seal strength of flexible packaging materials. Its advanced features include precise temperature control, adjustable sealing pressure, and customizable test parameters, ensuring accurate and reliable results.Figure 1 shows a typical probe tack test result. The 0.15 mm adhesive attached to a flat steel plate was compressed and released at a rate of 0.1 mm/s. It was squeezed in the time scale of 1 to 2 seconds and then pulled in tension. The maximum release force is 1.53 N and the area is 7.15 N s under the

The HT-2PC Hot Tack Tester is a highly technical instrument designed to measure the ‘Hot Tack Seal Strength’ of flexible packaging materials. It follows the principles of ASTM F1921 Standard Test Method for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and blends comprising the sealing surfaces of flexible webs.HTT-L1 Hot tack (Hot Seal Strength) tester is applicable in hot tack property test for plastic film, laminated film and other packaging film. Meanwhile, it is applicable in peel, shear, tension and other test items for adhesive, adhesive tape, .Hot tack testing plays a critical role in selecting optimal hot sealing parameters for FFS lines. By identifying materials with superior hot tack properties, manufacturers can achieve higher production efficiency through faster sealing .

hot tack strength

This paper, however, will discuss two important aspects of hot tack testing: the multilayered structure with a “hot tack” sealant and methods for relating test results to actual packaging machine performance, with major emphasis on two popular test methods–the automatic test equipment and the spring test.C632M Hot Tack Tester is to determine hot tack seal strength tests of packaging films according to ASTM F1921. Google Reviews. . Transmission rate test of hazardous gases such as hydrogen and methane, etc. Transmission rate test of organic gases such as benzene, ester, alcohol and ketone, etc.• The SL-10 Hot Tack Tester & Seal Tester is equipped Conforms to ASTM F1921 for hot tack seal testing • Direct touch color screen • Computer controlled pressure, temperature and dwell time • Windows® 7 Professional 32-bit operating system • Ethernet port, Printer Port, 2 .

Hot tack testing choices We make a range of hot tack test method devices and accessories. For example, check out the Testing Machines Inc Heat Sealer TS-12 75-58 or the Heat Sealer TS-4 with Interchangeable Seal Jaws 75-59. Heat sealer testing insight We like to share the knowledge we have amassed over the decades at Industrial Physics.

II. Standards. ASTM F1921, ASTM F2029, GB/T 34445, QB/T 2358, YBB00122003. III. Working Principle. Align and overlap two test samples, clip one end in clips, two samples each spread over upper side and lower side of impact bar, and pass through the hot tack entrance; then the heat sealed two samples are pulled quickly to the impact bar, and forced off by the impact bar; the .Equipment Summary: VIP 131 Hot Tack Tester measures the strength of heat seals formed between thermoplastic surfaces immediately after the seal has been made and before it cools to room temperature.. Standard Compiled: ASTM F1921, ASTM F2029 Features: Hot tack, heat seal, peeling and tensile test items are available; I.D. temperature controlSpecialist test equipment for materials: heat seal testing, hot tack testing, laboratory heat sealers, laboratory tray sealers, low pressure heat sealers, cold sealers, hot roll laminators, seal strength test equipment, friction test equipment, falling dart impact testers, laboratory carton tester, gelbo flex tester, haze, transmittance and .SL-10 Hot Tack Tester & Seal Tester Standard Features • Conforms to ASTM F1921 for hot tack seal testing • Direct touch color screen • Computer controlled pressure, temperature and dwell time • Ethernet port, Printer Port, 2 USB Ports, PS/2 Keyboard Port, VGA Monitor Port • Independent upper & lower sealing temperatures • Dual load .

This paper, however, will discuss two important aspects of hot tack testing: the multilayered structure with a “hot tack” sealant and methods for relating test results to actual packaging machine performance, with major emphasis on two popular test methods–the automatic test equipment and the spring test. El hot tack es importante en especial en los procesos de conversión en donde el producto cae con fuerza dentro de un envase poco después que se ha sellado el fondo, como lo que ocurre en las máquinas tipo FSS (Form, Fill and Seal). La selección de una capa sellante debe tener en cuenta el peso del producto y la fuerza a la cual cae en el .

tear lactoferrin test

tear meniscus height test

Kelsi Monroe hot outdoor fuck onlyfans. Full 1080p -> streamtape.com ( Telegram Backup @leakedhard) #brunette #bigtits #rough #Hardcore #hardsex #new #latest #bigass .

Hot Tack Testing|hot tack strength